Have you ever considered how software integration could revolutionize the manufacturing of high-frequency PCBs?

Imagine the possibilities of streamlining design processes, optimizing material usage, and ensuring precise production outcomes. By harnessing the power of software tools, manufacturers can achieve unparalleled levels of accuracy and efficiency in crafting high frequency PCBs.

But what exactly are the specific benefits that software integration brings to this intricate manufacturing process?

The answer lies in a combination of enhanced precision, accelerated production speeds, and improved quality control that ultimately shape the future landscape of high-frequency PCB fabrication.

Post Contents

Key Takeaways:

- Precision enhancement through advanced software tools ensures accurate design simulations and optimized layout for minimal signal interference.

- Real-time monitoring accelerates production speeds by tracking progress, identifying bottlenecks, and optimizing schedules.

- Quality improvement is achieved with high-quality materials, rigorous inspections, advanced testing, and continuous enhancement strategies.

- Challenges in software-driven manufacturing include complexity, updates, employee proficiency, compatibility, and integration understanding.

Precision Enhancement Through Software Integration

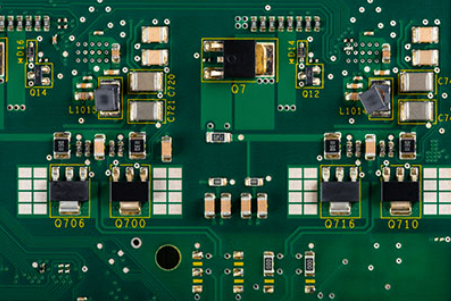

By integrating advanced software tools, you can significantly enhance the precision of high-frequency PCB manufacturing processes. These tools allow for more accurate design simulations, enabling you to detect and rectify potential issues before they impact production. Through software integration, you can optimize the layout of components and routing paths, ensuring minimal signal interference and better signal integrity. This precision in design translates to improved overall performance and reliability of the final PCB product.

Additionally, software tools provide real-time monitoring and analysis capabilities during the manufacturing process. By leveraging these features, you can identify deviations from desired specifications promptly and make immediate adjustments to maintain quality and precision. The ability to visualize the production process and monitor key parameters in real-time enables you to proactively address any potential issues that may arise, ultimately leading to higher precision in the final high-frequency PCB product.

Accelerating Production Speeds With Software Tools

Boost production speeds using cutting-edge software tools to streamline high-frequency PCB manufacturing processes. By leveraging advanced software solutions, you can significantly enhance efficiency and reduce lead times in your production line. Here are some ways these tools can accelerate your manufacturing speeds:

- Real-time Monitoring: Stay updated on production progress and identify bottlenecks instantly.

- Automated Scheduling: Optimize production schedules for maximum output without manual intervention.

- Predictive Maintenance: Anticipate equipment failures before they occur, minimizing downtime.

- AI-driven Optimization: Utilize artificial intelligence to fine-tune processes and boost overall productivity.

With these software tools at your disposal, you can revolutionize your manufacturing operations, meeting tight deadlines and increasing output capacity. Embrace technology to propel your high-frequency PCB production to new heights, staying ahead of the competition in today’s fast-paced industry.

Quality Improvement in High-Frequency PCB Fabrication

To enhance the overall efficiency and reliability of high-frequency PCB fabrication, focus on implementing robust quality improvement strategies. Quality improvement in high-frequency PCB fabrication is crucial for ensuring the performance and reliability of the final products. One key aspect to consider is the selection of high-quality materials that are specifically designed for high-frequency applications. These materials can help minimize signal loss, impedance variations, and other issues that can affect the functionality of the PCB.

Additionally, implementing rigorous inspection and testing processes throughout the fabrication stages is essential. This includes conducting thorough quality checks during material procurement, fabrication, and assembly. By identifying and addressing any defects or irregularities early on, you can prevent costly rework and ensure that the final PCB meets the required specifications.

Furthermore, investing in advanced testing equipment and technologies can significantly enhance the quality control process. Techniques such as impedance testing, signal integrity analysis, and thermal profiling can help identify potential issues and optimize the performance of high-frequency PCBs. By continuously refining and improving your quality improvement strategies, you can elevate the overall quality and reliability of your high-frequency PCB fabrication process.

Overcoming Challenges in Software-Driven Manufacturing

Overcoming challenges in software-driven manufacturing requires a deep understanding of the integration process and its impact on production efficiency. Embracing these challenges head-on can lead to significant improvements in the manufacturing process of high-frequency PCBs. Here are some key factors to consider:

- Complexity of Integration: Navigating the intricate web of software systems and machines can be daunting but mastering this complexity is crucial for success.

- Maintenance Demands: Constant updates and maintenance of software tools are necessary for optimal performance, adding to the workload of manufacturing teams.

- Training Needs: Ensuring that employees are proficient in using the software tools is essential but can be time-consuming and resource-intensive.

- Integration Hurdles: Overcoming compatibility issues between different software platforms and hardware components can be a major roadblock in the integration process.

Future Outlook: Innovations in PCB Software Integration

Innovative advancements in PCB software integration are shaping the future landscape of high-frequency manufacturing processes. The future outlook for PCB software integration is poised for exciting developments. One of the key innovations on the horizon is the increased use of artificial intelligence (AI) and machine learning algorithms to optimize the design and manufacturing processes of high-frequency PCBs. These technologies can analyze vast amounts of data to identify patterns, predict outcomes, and enhance overall efficiency.

Furthermore, the integration of augmented reality (AR) and virtual reality (VR) tools into PCB software is set to revolutionize the way manufacturers interact with and visualize PCB designs. By providing immersive and interactive experiences, AR and VR technologies offer a new dimension to the design and testing phases, leading to improved collaboration and faster decision-making.

Additionally, advancements in cloud-based software solutions are expected to streamline communication and data sharing among global teams, facilitating real-time collaboration and enhancing productivity. Overall, the future of PCB software integration holds great promise for driving innovation and efficiency in high-frequency PCB manufacturing processes.

Frequently Asked Questions

How Does Software Integration Impact the Cost of Manufacturing High-Frequency PCBs?

When integrating software into manufacturing high-frequency PCBs, you streamline processes, cut down on errors, and improve efficiency. This reduces costs by enhancing precision, minimizing waste, and optimizing resources. Embrace software integration for cost-effective production.

Can Software Tools Help in Predicting and Preventing Potential Defects in the Manufacturing Process of High-Frequency PCBs?

Yes, software tools can certainly aid in predicting and preventing potential defects in manufacturing high-frequency PCBs. They enhance efficiency and accuracy, allowing you to identify issues early on and take proactive measures to ensure product quality.

What Are the Key Considerations for Selecting the Right Software Tools for High-Frequency PCB Fabrication?

When selecting software tools for high-frequency PCB fabrication, focus on compatibility with your existing equipment, ease of integration, support for complex designs, and accuracy in simulation. These factors ensure efficient production and quality outcomes.

How Does Software Integration Improve Collaboration and Communication Among Different Departments Involved in PCB Manufacturing?

When integrating software into your PCB manufacturing process, it streamlines collaboration and communication among departments. This boosts efficiency, reduces errors, and ensures everyone stays on the same page throughout the production cycle.

Are There Any Regulatory Compliance Issues to Consider When Implementing Software-Driven Manufacturing Processes for High-Frequency PCBs?

When implementing software-driven manufacturing processes for high-frequency PCBs, you must consider regulatory compliance issues. Ensuring adherence to industry standards and regulations is crucial to maintaining quality and reliability in your production processes.